The Fitzpatrick Company pioneered the development of particle size reduction and forming technology, with the development of the Lab Compaction System, Contained Compaction System roll compactor and FitzMill, Fitzpatrick has been constantly evolving powder processing technology and in conjunction with Quadro developed the Scalable Lab System.

Fitzpatrick Hammer Mills produce the smaller PSDs and are more suited to hard and difficult to mill products. They are the mill of choice when you need to precisely control the particle size reduction process.

It is important to get the feed throat angle matching the material characteristics; a vertical inlet for fragile material or horizontal for fine grinds.

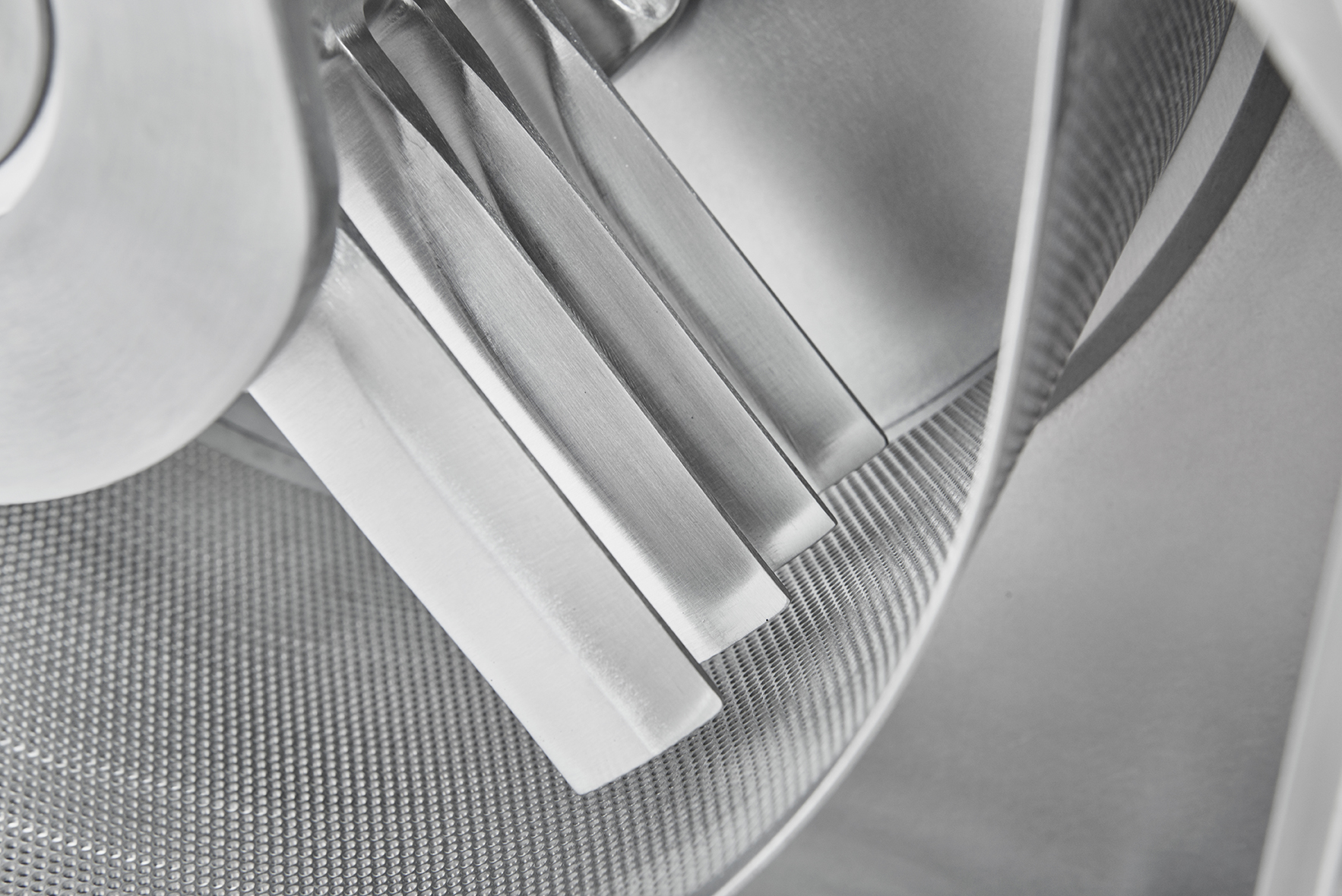

The blades can be knife-edged for “cutting effet” or blunt-edged for more impact and aggressive particle size reduction. A blade with reversible edges becomes truly versatile, being able to match any product requirement.

- Applications:

- Impact Milling,

- Milling

- Size reduction for the pharmaceutical, food and chemical industries

- Capacities from 50 g up to 100 tons/h

- Wide range of blades available

- CIP/WIP and cGMP designs for the pharmaceutical applications

- Product Containment System (PCS) for toxic and hazardous products

- Reduced explosion hazard with milling in an inert atmosphere (ATEX)

- Customized design to suit specific process needs

- Automated controls, if required designed to be compliant to GAMP 5.0 and 21 CFR part 11