Quadro Engineering, the innovators of the Comil conical screen mill, continue to develop and innovate with new products such as the new Scalable Lab System (SLS), the U21 high efficiency Comil, the High Energy H20 Comil for API milling, the in-line FlexSift for security screening and the F10 fine grinding mill. Quadro milling and vacuum transfer systems are used in a wide range of powder processing applications in the Food, Pharmaceutical and Cosmetics industries

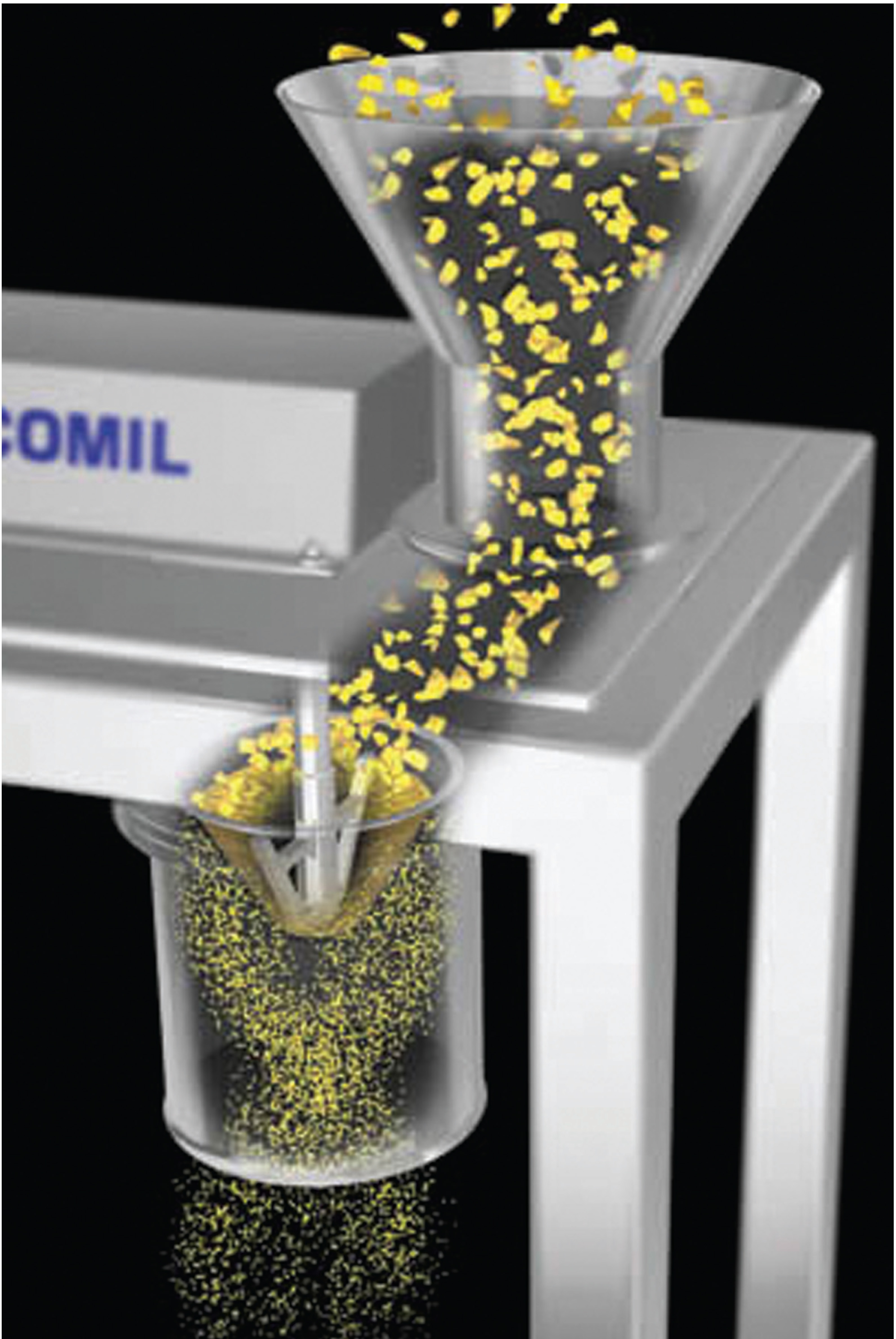

The Quadro Comil Overdriven unit was the original conical screen mill developed by Quadro Engineering in the 1970s for uniform size reduction and deagglomeration and it is used in many industries across the world.

- Applications:

- Laboratory and Pilot Scale Equipment,

- Milling

The Overdriven Comil is used in major manufacturing facilities in more than 50 countries around the world for uniform size reduction or deagglomeration of wet, dry, heat sensitive, sticky or fatty products. With many tooling options and combinations gained from decades of experience, the Comil can process many powder/granulated products. The Comil can be integrated into any system or process with the design expertise, flexibility and support offered by Quadro.

Benefits of the Overdriven Comil:

- Uniform Particle Size Distribution

- Positive 360° Product Discharge

- High Capacity

- Choke/Flood Fed

- Easy Clean Design (CIP Available)

- Low Dust

- Low RPM/Energy Consumption

- Low Noise

- Various Frame/Feed/Discharge Designs

The Comil also has special tooling designed for the delumping of packaged fruit.

Comil Model |

197 |

194 |

196 |

198 |

199 |

|

Capacity (kg/hr) |

360 | 1,8003a | 3,6003b | 7,2003c | 14,4003d | |

Approximate Dimensions (mm) |

L | 572 | 1050 | 1270 | 1730 | 2130 |

| W | 318 | 700 | 890 | 890 | 1170 | |

| H | 802 | 1620 | 1740 | 1730 | 2110 | |

Screen Diameter (mm) |

127 | 203 | 305 | 603 | 761 | |

Motor Power (kW) |

1.5 | 4 | 7.5 | 15 | 22 | |

- Capacities are based on standard pharmaceutical placebo with 3% crystalline cellulose (CMC).

- Capacities may vary significantly based on product characteristics, particle granulometry, inlet and discharge conditions.

- For some products, capacities may reach the following higher limits: (a) 6,800kg/hr, (b) 15,900kg/hr, (c) 27,000kg/hr, (d) 54,500kg/hr.

- Dimensions are based on stand alone units and not integrated into a process system.