Ytron specialise in the design, innovation and manufacture of a range of mixers and homogenisers for the production of homogeneous, air free liquids pastes and suspensions, with over 40 years application experience in all areas of industry including Food, Beverage, Dairy, Pharmaceutical, Cosmetic and Chemical processes.

- Applications:

- Powder Dispersion,

- Powder Incorporation

Principle:-

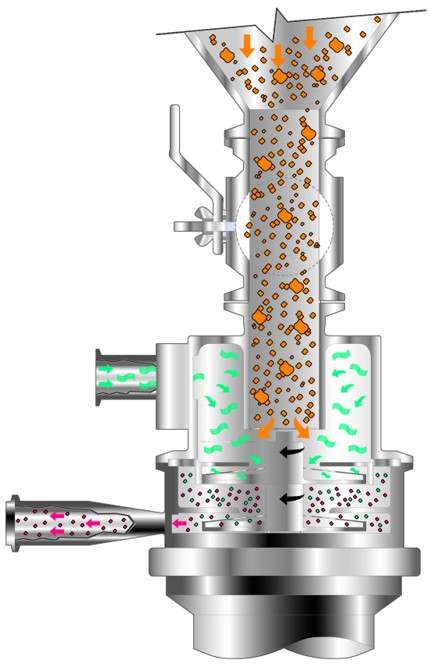

Powders and compounds with a tendency to form lumps are continuously incorporated inline and effectively dispersed. This means that even in a single pass, very high concentrations can be achieved.

The first stage in the reactor head creates a strong negative pressure and sucks the solids phase in.

Immediately after contact with the liquid phase, this premix of the 2 phases is impelled against the XC impact chamber plates where the powder is dispersed/dissolved into the liquid phase.

The second stage discharges the homogeneously wetted product.

Advantages of YTRON-XC

- Complete wetting out of the powders in a single pass

- Concentrations of up to 40% are possible in a single pass

- No air entrainment other than the air included in the powder phase

- Batch time reduced to a minimum

- Higher product yield due to the intensive wetting of the powders

- Low intensity mixing due to high impact frequency instead of high shear

- Feeding directly from Big Bag or silo is possible

- CIP and SIP available