YTRON specialise in the design, innovation and manufacture of a range of mixers and homogenisers for the production of homogeneous, air free liquids pastes and suspensions, with over 40 years application experience in all areas of industry including Food, Beverage, Dairy, Pharmaceutical, Cosmetic and Chemical processes.

High shear homogeniser for the size reduction and emulsion generation of slurries and liquid/liquid applications in continuous or recirculation processes.

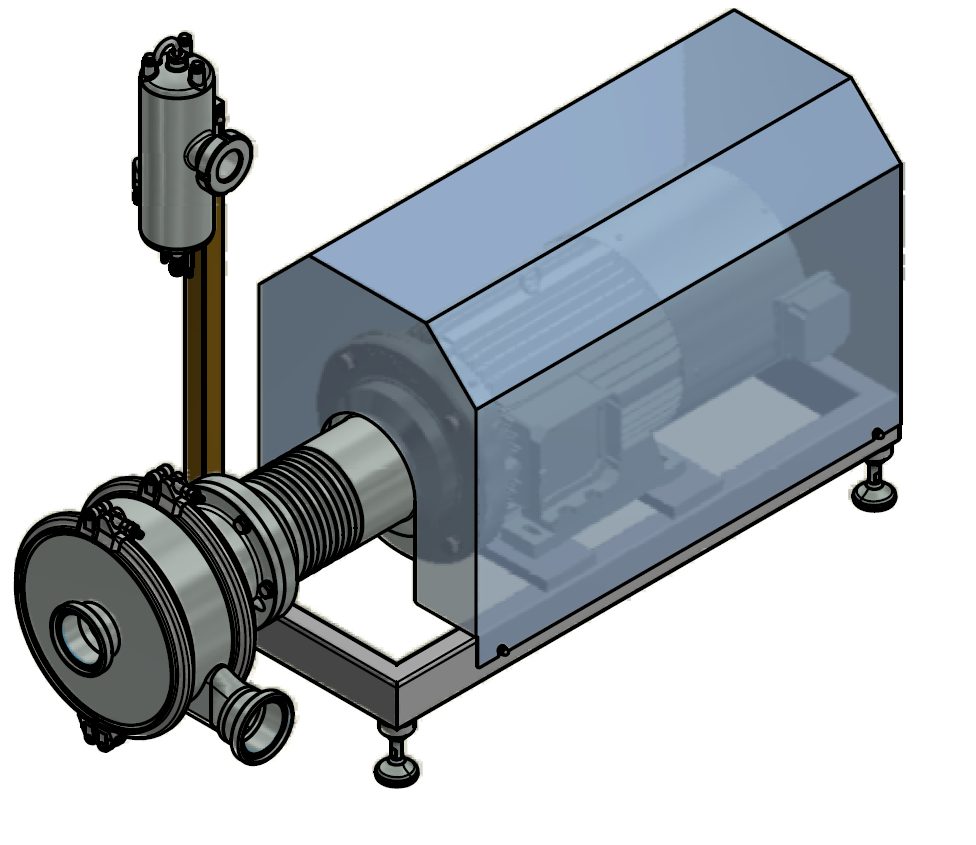

YTRON Z vs High Pressure Homgeniser – footprint comparison

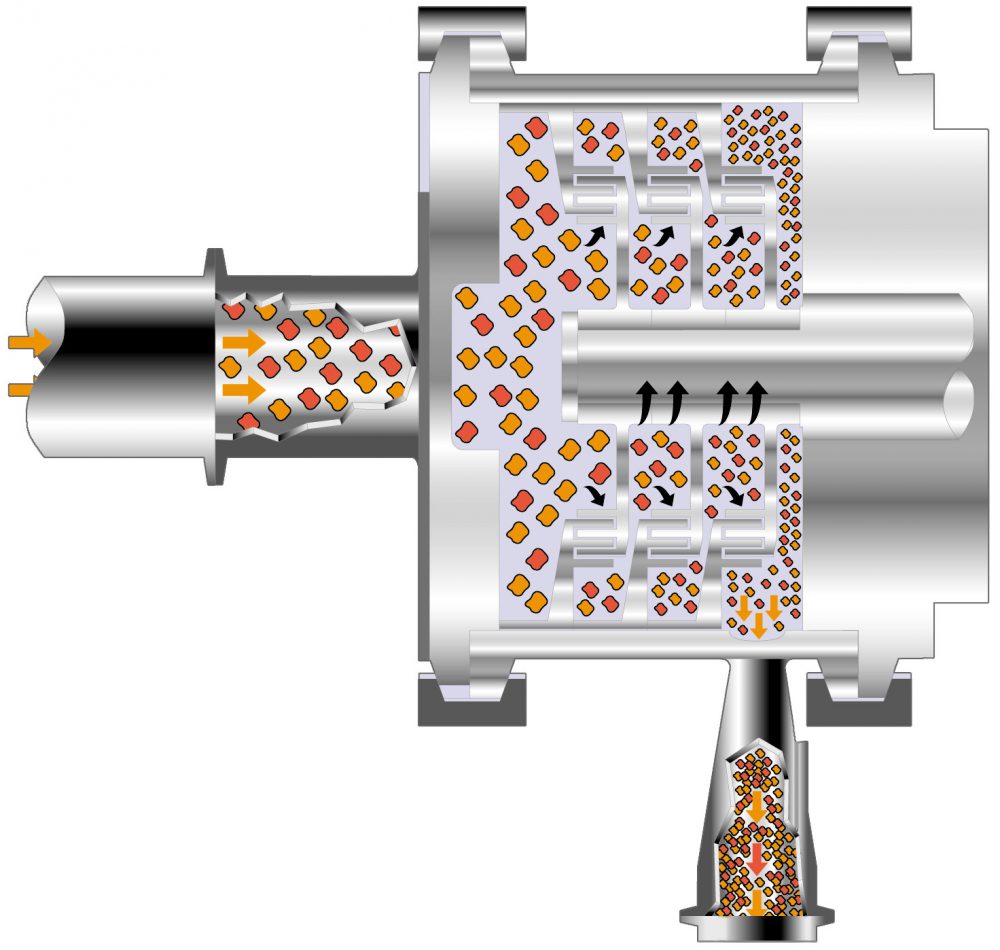

Principle:-

One or more liquid phases, unsuspended particles or inhomogeneous slurries are passed through a forced-feed passage within the rotor/stator system. The In-line principle effects a defined, reproducible and scalable application of shear forces.

With the parameters of slot width, number and distance of the shear slots, number of rotor/stator sets used, rotational speed and flow rate, the desired dispersing or homogenising effect, can be infinitely adjusted.

Conventional batch processes often require recirculation and lead to a localised over-shearing of the product. This also leads to irregular treatment of the batch.

In contrast, the YTRON-Z ensures a homogeneously and reproducibly dispersed product in a single pass.

Advantages of YTRON-Z

- The forced feed passage allows reproducible results

- Gentle treatment of shear sensitive products, e.g. STRETCHING of yoghurt, direct curd products, fromage frais and cream cheese at low speed

- High speed operation to effect a continuous emulsificaton reaching a droplet size as low as 1 µm for various emulsions (o/w and w/o) and dispersions

- Up to three slotted rows of teeth with variable slot widths and finest distance of the slots in each rotor/stator set

- Reactor chamber houses up to three rotor/stator-sets

- Hygienic execution available for use in the food, cosmetic and pharmaceutical industry