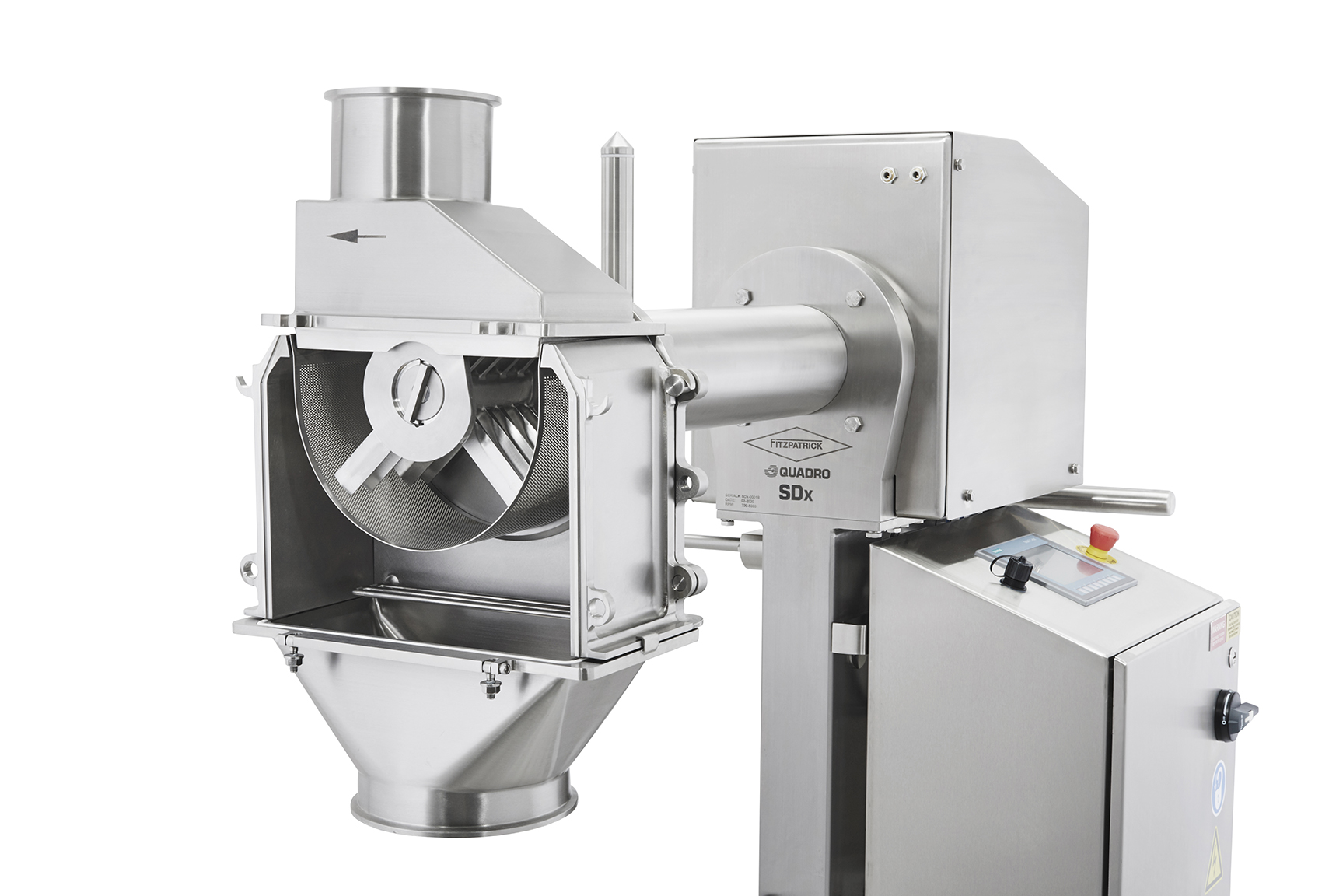

Quadro Engineering, the innovators of the Comil conical screen mill, continue to develop and innovate with new products. The newest development is SDx Series which combines the Quadro Flexsift and the Fitzpatrick Hammer Mill. All three process heads are interchangeable on the same drive platform which uses Smart-Detect to ensure the process head is operating in the correct operating parameters. The SDx is used in a wide range of powder processing applications in the Food, Pharmaceutical and Cosmetics industries.

Quadro Engineering Corp. and The Fitzpatrick Company have launched the SDx Series – Smart Drive Exchangeable Platform, the world’s first production-scale milling and screening platform offering three distinct powder processing solutions on a single, common drive. They include Fitzpatrick’s FitzMill, Quadro’s Comil and FlexSift Security Screening technologies.

The new platform gives operators the ability to quickly and easily interchange the three heads in order to fulfil specific processing requirements, improve production efficiencies and reduce bottlenecks. Like the SLS-Scalable Lab System, the SDx Series utilises SMART-detect, a unique equipment feature that automatically recognises the head being installed and adjusts RPM to the appropriate level for optimum material processing, thereby eliminating operator error. This makes each process scalable and repeatable to ensure the same target particle size distribution you achieve today on Fitzpatrick and Quadro equipment is still achievable with the SDx, with the added benefit of reduced capital investment and overall equipment footprint.

- Applications:

- Impact Milling,

- Milling,

- Security Screening,

- Wet Mass Granulation

Key features:-

- 3 interchangeable process solutions on a single common drive

- Suitable for both continuous and batch production environments

- Suitable for dry milling and/or wet material conditioning

- Minimal product losses/hold-up

- Repeatable PSD and capacity rates from existing models

- Sanitary greaseless gearbox/drives

- Manufactured to cGMP guidelines

Typical applications for the SDx Series

- Dry powder deagglomeration and size reduction

- Sizing and grading of powders

- Wet mass granulation for efficient and even drying

- Fine particle size reduction

- Size reduction of heat sensitive products

- Security screening of free flowing and sticky products