VMI, with over 50 years experience in developing and manufacturing mixing technology lead the way in the mixing of cosmetic and pharmaceutical creams and lotions. The equipment range includes laboratory scale mixers for atmospheric and vacuum mixing requirements and large scale vacuum processing systems.

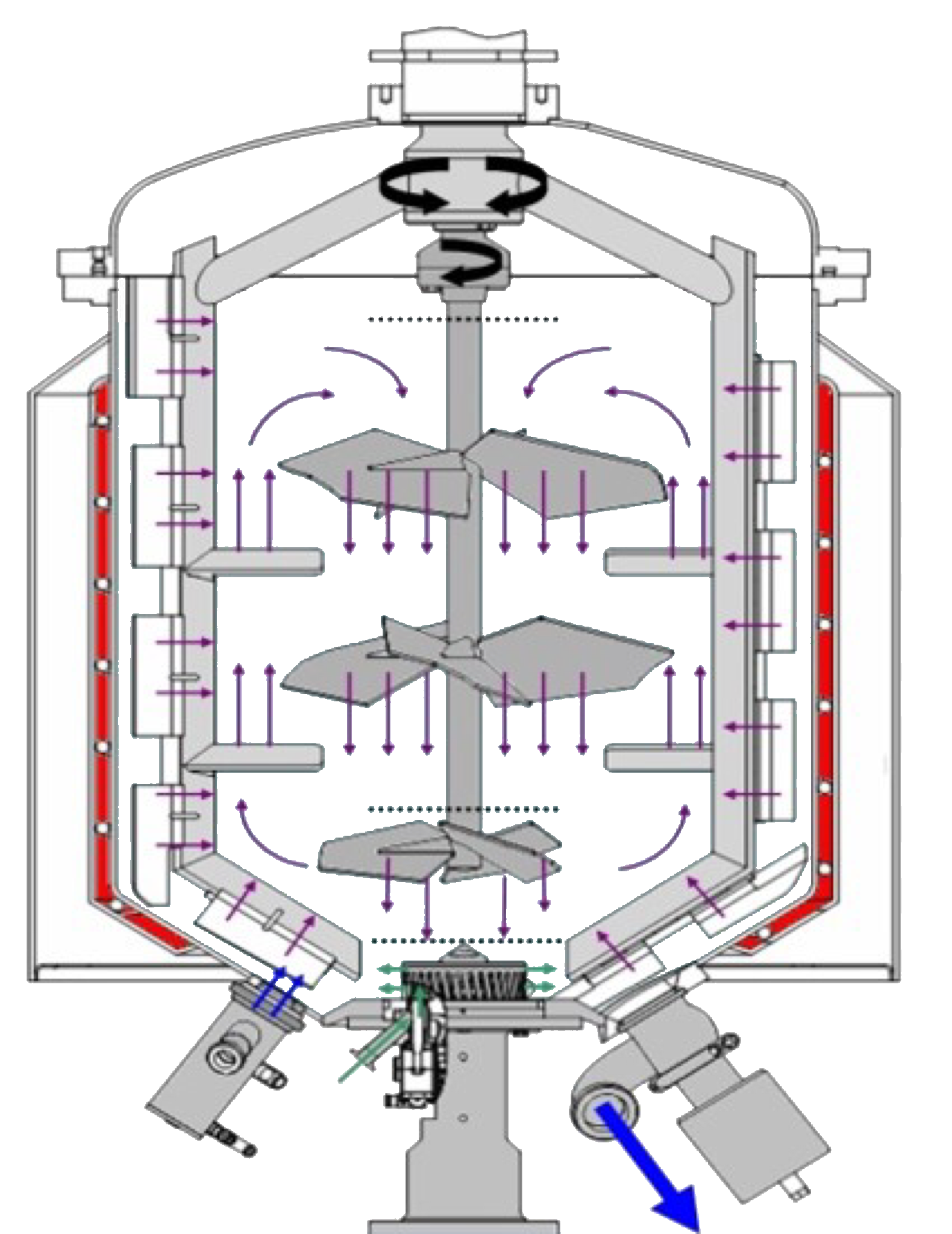

The VMI TRIMIX is a complete three stage mixing solution for the manufacture of creams and pastes. with options for integrated vacuum mixing system, wax melting, heating and cooling the TRIMIX can be used as a stand alone mixer or part of a larger system.

- Applications:

- Cream and Paste Mixing,

- Homogenisation,

- Mixing,

- Powder Incorporation

Key Features:-

- No external recirculation loop gives full control of mixing and minimises losses

- Designed for extremely high product recovery

- Fully scalable from TRILAB & ULTRALAB

- Integrated Turnkey system for a complete production process

- Working volumes up to 20,000 litres

- Premix vessels can be integrated with a range of mixing tools

- Vacuum mixing for process and product introduction

- Designed for easy clean and simple removal of tooling

- CIP available

Typical Applications for TRIMIX:-

- Viscous, Paste like products

- Hand Creams & Sanitisers

- Shampoos, Conditioners, Body Washes

- Pharmaceutical Rubs & Oitnments

- Complex formulations & rheologies